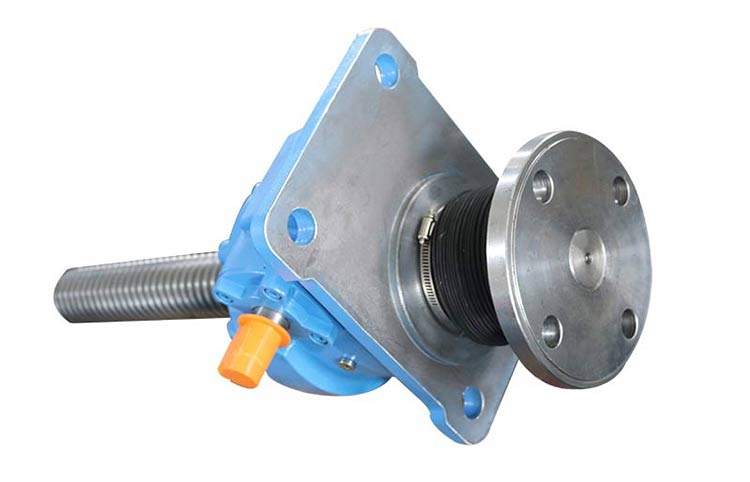

Screw Lift Common Solution

Worm gear screw lifts are widely used, but at the same time, there are often some problems. For these problems arising from the worm gear screw lifts, Lude Transmission will organize and share solutions for everyone, and hope to be useful to everyone.

What are the causes and treatments of the worm gear screw lift during normal use?

The causes of the vibration of the screw lifter after the additional load during use are the uneven worm splitting, the uneven pitch of the lead screw, the over-tightening of the upper and lower sheaths of the lead screw, the flat pressure bearing and the quality of the tapered bearing, and the installation. Disagreement. Just check it and reinstall it according to the installation instructions.

What are the reasons for the excessive temperature rise and the death of the screw lift and how to deal with it?

The maximum temperature of the screw lifter under normal working conditions shall not exceed 45 degrees Celsius. If the high temperature occurs, the machine inspection shall be stopped immediately. The general reason for this problem is that the screw lift of this tonnage is too small and overloaded, or the worm and the worm wheel end cover are used. In conjunction with the high temperature conditions that are too tight, the input speed is not excluded. The worm gear screw jack is a grease-lubricated screw lift. The maximum speed of the worm shaft must not exceed 1000min/s. If the input speed is too high, high positions and jams may occur. The high temperature treatment method is to reduce the input speed, check whether the insert fit of the gland is too tight and whether the screw lift is short of oil.

评论

发表评论