What is the difference between ball screw jack and trapezoidal screw jack?

What is the difference between ball screw jack and trapezoidal screw jack?

When to use ball screw jack, When to use trapezoidal screw jack?

Let’s look at the difference between ball screw jack and trapezoidal screw jack with these questions, and explain it roughly from the following 7 aspects.

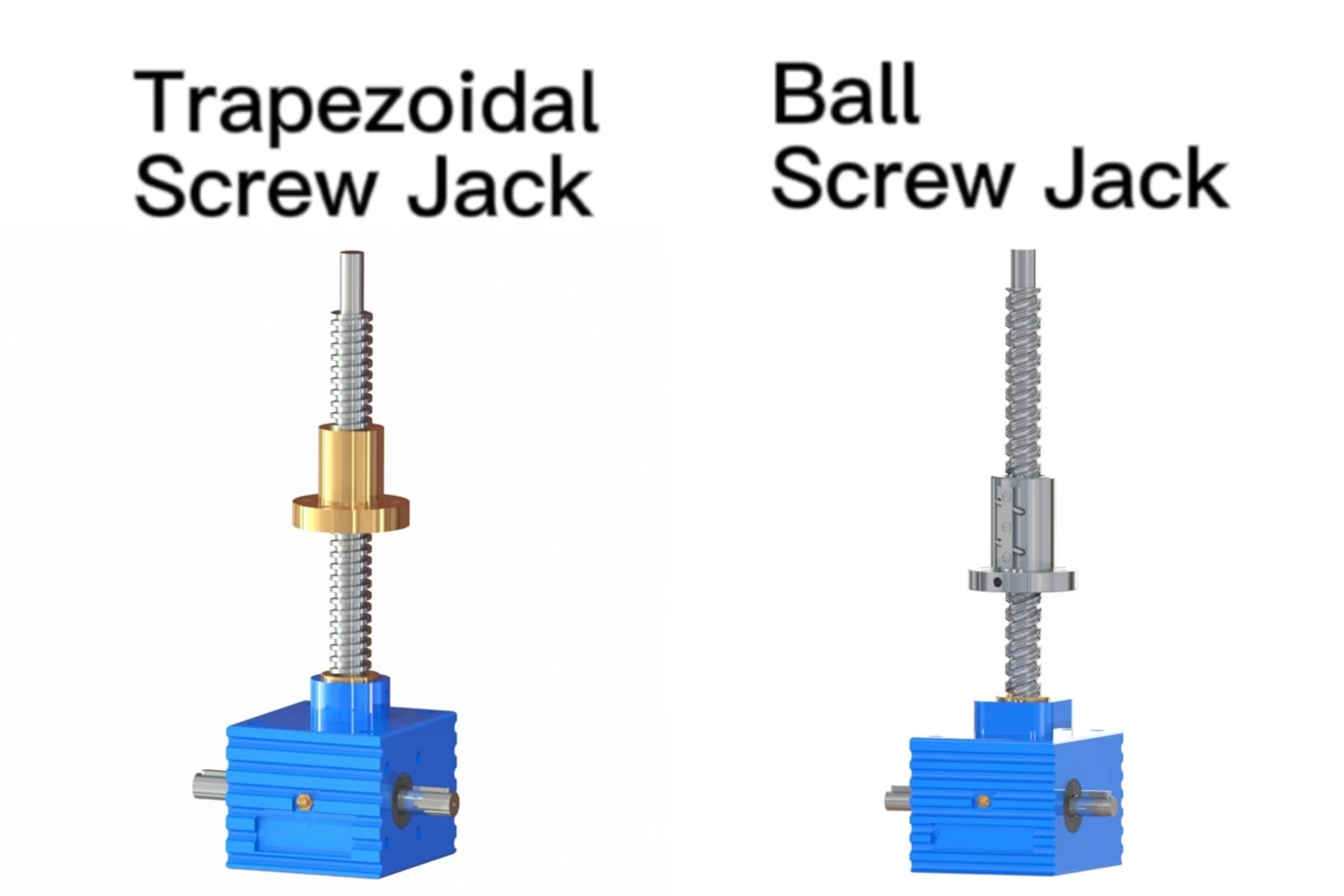

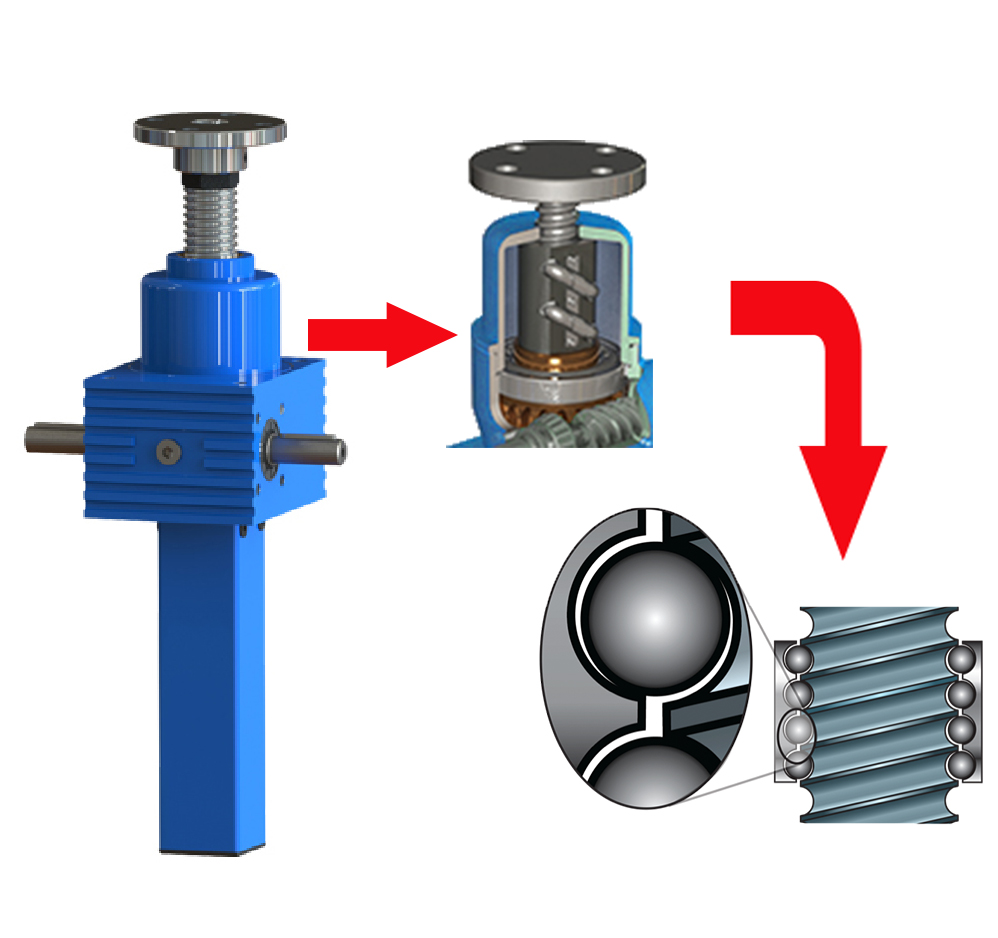

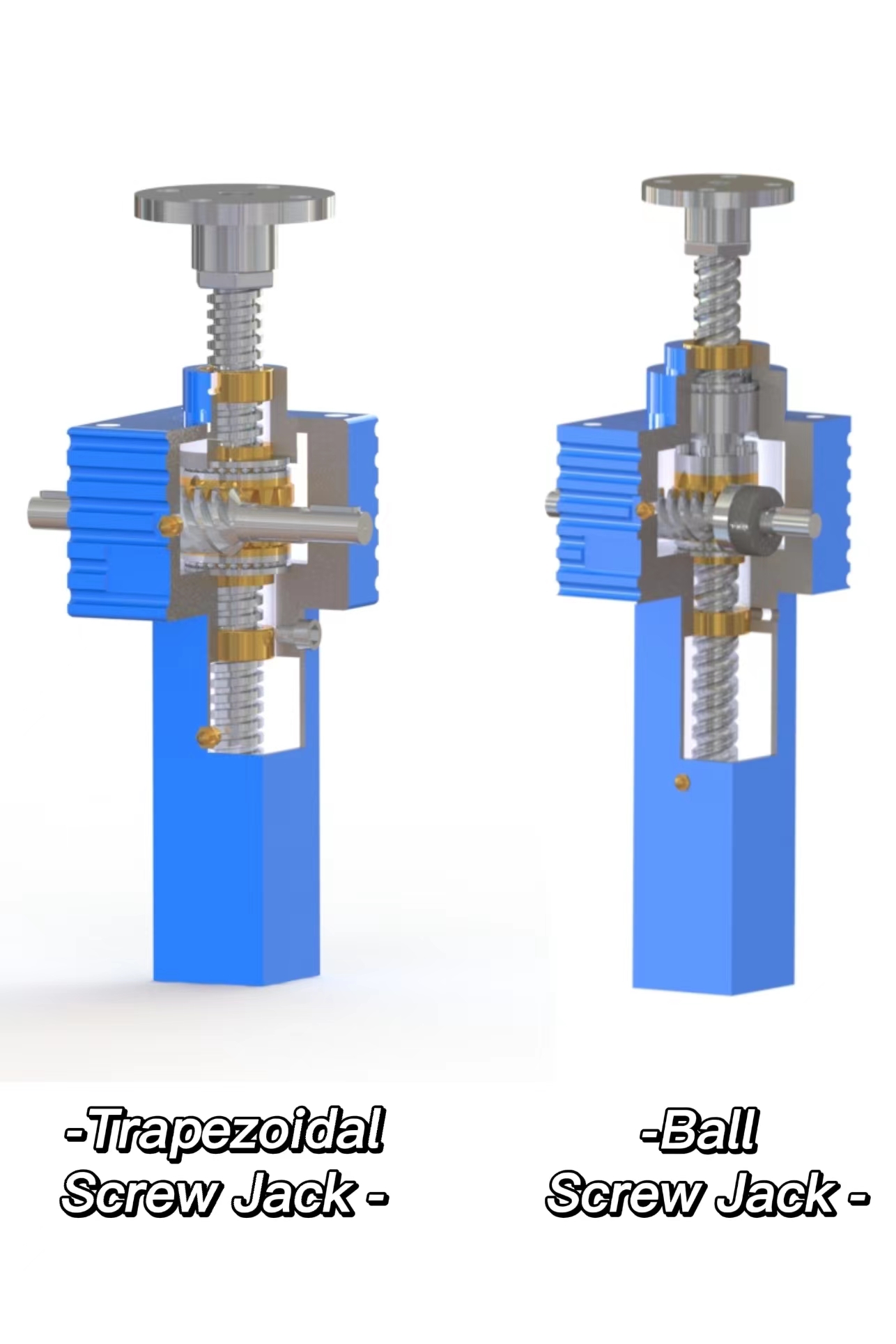

1. Different structures.

The movement principle of trapezoidal screw jack and ball screw jack

is the same, but the difference is that there is no ball in trapezoidal

screw, so the movement between nut and screw shaft depends entirely on

mechanical contact to produce sliding

2. Different transmission efficiency.

The transmission efficiency of most ball screws is as high as 90%, and some even reach more than 95%, while the transmission efficiency of most trapezoidal screws is lower than 70%. trapezoidal screw is not suitable for high-speed operation, and its maximum speed is generally not more than 3000RPM. And the ball screw, because it is rolling friction, does not generate so much heat, and its speed can reach very high, such as 10000RPM. The efficiency of ball screw is 2-4 times that of trapezoidal screw, so generally speaking, when the same lead is used to drive the same load, ball screw has more advantages.

3. Different self-locking

Ball screw has no self-locking, while trapezoidal screw has certain self-locking .

4. Different materials

The ball screw shaft is generally made of stainless steel or alloy steel.

5. Different manufacturing methods and final precision

Generally, there are two processing methods for ball screw jack, one is grinding and the other is tying. Trapezoidal screw jack has three manufacturing methods: rolling, cutting and grinding.

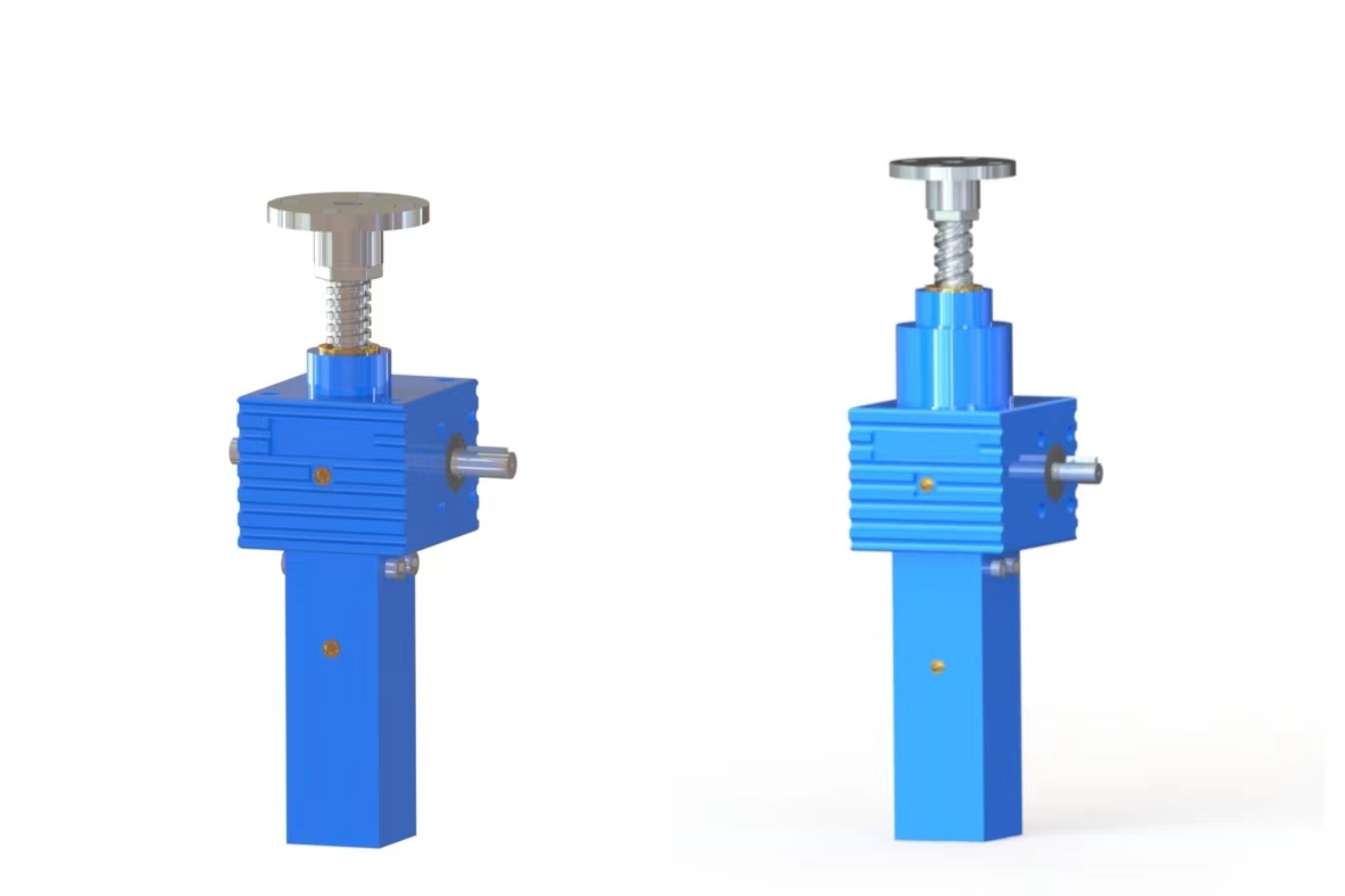

6. Differences in applications.

Trapezoidal screw jack

is sliding friction, too high speed will produce high heat on the joint

surface, which will lead to increased wear. Therefore, trapezoidal lead

screw jack is

suitable for applications with light weight and low speed requirement.

At the same time, trapezoidal lead screw, because of its low precision,

is often more suitable for applications that do not require high

precision, such as slow transfer and handling. Ball screw, with low heat

and high precision, is usually more suitable for applications requiring

smooth motion, high efficiency, high precision and long-time continuous

or high-speed motion.

7. Example of calculation and selection of ball screw jack.

Finally,

how to choose the ball screw according to the conditions of precision,

speed, load and service life? “How to choose ball screw jack”, contact us and we will share it with you. www.ludetransmission.com

评论

发表评论