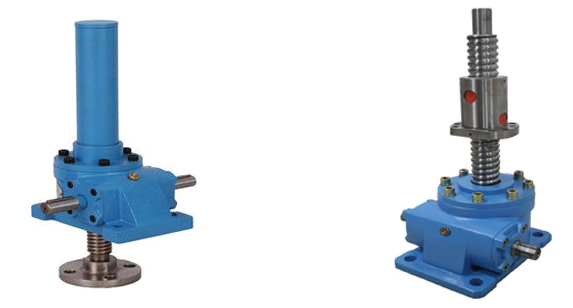

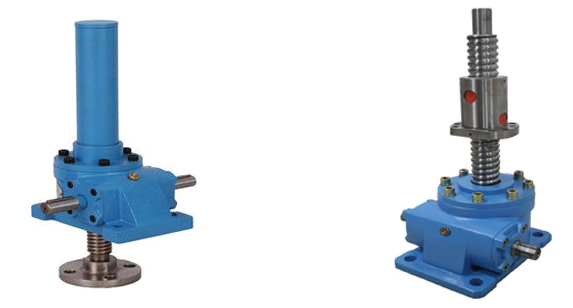

When to choose Ball Screw Jacks vs. ACME Machine Screw Jacks?

Worm Gear Screws Jacks

can provide long duty life, high load capacity and flexible design. Its

two major categories ball screw jack and acme machine screw jack are

common used screw jacks. How to determine which one is suitable for your

application? There are some tips for you.

Ball Screw Jacks use a ball screw and nut made from hardened alloy steel with bearing balls carrying the load between nut & screw. This rolling action reduces the friction between nut and screw, permitting smooth and efficient load movement that requires approximately 1/3 less torque than a machine screw jack with the same load.

Machine Screw Jacks

incorporate an alloy or sometimes stainless steel worm which drives a

high strength bronze worm gear, or drive sleeve. The worm shaft is

supported on anti-friction tapered roller bearings with external seals

that prevent lubrication loss. The drive sleeve can also be supported on

tapered roller bearings, or ball thrust bearings. Rotation of the drive

sleeve causes the acme thread lifting screw to translate or rotate,

depending on the jack configuration.

Machine Screw Jacks

incorporate an alloy or sometimes stainless steel worm which drives a

high strength bronze worm gear, or drive sleeve. The worm shaft is

supported on anti-friction tapered roller bearings with external seals

that prevent lubrication loss. The drive sleeve can also be supported on

tapered roller bearings, or ball thrust bearings. Rotation of the drive

sleeve causes the acme thread lifting screw to translate or rotate,

depending on the jack configuration.

Because of their efficiency and lower power requirements, Ball Screw Jacks are often preferred. However, several factors can make Machine Screw Jacks preferable. For quick reference …

Machine Screw Jacks are best used for:

• Resistance to backdriving

• Environments with vibration

• Manual operation

• High static loads

• Corrosion resistance (with stainless steel versions)

Ball Screw Jacks are preferred for:

• Long travel lengths

• Long, predictable life

• High duty cycles

• Oscillating motion

Well,hope the above information can help you to choose suitable screw jacks. After determine which kind of screw jacks, you can choose suitable types(like Upright, Inverted, Upright Rotating and Inverted Rotating),you can also come to learn How to choose suitable screw jack for further information.

Ball Screw Jacks use a ball screw and nut made from hardened alloy steel with bearing balls carrying the load between nut & screw. This rolling action reduces the friction between nut and screw, permitting smooth and efficient load movement that requires approximately 1/3 less torque than a machine screw jack with the same load.

Because of their efficiency and lower power requirements, Ball Screw Jacks are often preferred. However, several factors can make Machine Screw Jacks preferable. For quick reference …

Machine Screw Jacks are best used for:

• Resistance to backdriving

• Environments with vibration

• Manual operation

• High static loads

• Corrosion resistance (with stainless steel versions)

Ball Screw Jacks are preferred for:

• Long travel lengths

• Long, predictable life

• High duty cycles

• Oscillating motion

Well,hope the above information can help you to choose suitable screw jacks. After determine which kind of screw jacks, you can choose suitable types(like Upright, Inverted, Upright Rotating and Inverted Rotating),you can also come to learn How to choose suitable screw jack for further information.

评论

发表评论