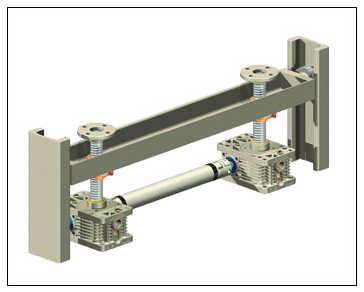

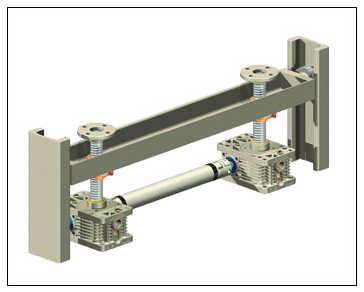

Screw Jack Alignment Is Very Important for Installation

On Aug.9th, we talked about how to install the screw jack.Now l’ll talk something more about the installation. That is about screw jack alignment .

Screw jack has the ability to turn rotary motion into tremendous linear force, within a compact envelope, is one of the miracles of mechanics.However, properly integrating a screw jack into a specific piece of machinery is no small feat. Beyond the actual selection of the appropriate size and configuration the mounting of a screw jack takes special care.

Screw jacks can take very little side load. Therefore any side

forces, either from weight or misalignment, must be minimized or

eliminated. This is usually accomplished by guiding the load with rails,

rollers or linear bearings of some type. It keeps the load moving in

the intended direction without undue strain on the nut, or internal

threads in the case of a traversing spindle, from something other than

the axial load it needs to move.

Screw jacks can take very little side load. Therefore any side

forces, either from weight or misalignment, must be minimized or

eliminated. This is usually accomplished by guiding the load with rails,

rollers or linear bearings of some type. It keeps the load moving in

the intended direction without undue strain on the nut, or internal

threads in the case of a traversing spindle, from something other than

the axial load it needs to move.

Aligning the guides to the jack (or vice versa), therefore, becomes one of the critical exercises in mounting screw jacks, or any other linear actuator for that matter. Otherwise it’s like trying to screw in a bolt that isn’t centered to the thread of a nut. It doesn’t want to go in without extreme force and usually results in thread damage.

A potential problem with this is that the boot is usually attached to a separate support structure. These structures have tolerances, and if they are welds rather than the processing frame, then they can be extensive. Even so, it is their own problem to install the machining frame accurately.

The key here is to understand the challenge of creating a design that allows the socket and load guidelines to be designed for parallelism and angle. Afterwards, the ability to perform design in the store is a real-world problem faced by many assembly technicians.

In order to get the best overall system design, we need to consider parallelism, angularity, type of guide system, mounting surfaces, distance between supports, lift distance, and all the tolerances. Everything will fall into place much easier after we think about all enough.

Lude Transmission is a worm gear screw jack supplier for 16 years,it has trapezoidal screw jack,ball screw jack,stainless screw jack and bevel gear screw jack. OEM and small order are acceptable. If you have any need for screw jacks,just feel free to contact us. Our website:https://www.ludetransmission.com/

Screw jack has the ability to turn rotary motion into tremendous linear force, within a compact envelope, is one of the miracles of mechanics.However, properly integrating a screw jack into a specific piece of machinery is no small feat. Beyond the actual selection of the appropriate size and configuration the mounting of a screw jack takes special care.

Aligning the guides to the jack (or vice versa), therefore, becomes one of the critical exercises in mounting screw jacks, or any other linear actuator for that matter. Otherwise it’s like trying to screw in a bolt that isn’t centered to the thread of a nut. It doesn’t want to go in without extreme force and usually results in thread damage.

A potential problem with this is that the boot is usually attached to a separate support structure. These structures have tolerances, and if they are welds rather than the processing frame, then they can be extensive. Even so, it is their own problem to install the machining frame accurately.

The key here is to understand the challenge of creating a design that allows the socket and load guidelines to be designed for parallelism and angle. Afterwards, the ability to perform design in the store is a real-world problem faced by many assembly technicians.

In order to get the best overall system design, we need to consider parallelism, angularity, type of guide system, mounting surfaces, distance between supports, lift distance, and all the tolerances. Everything will fall into place much easier after we think about all enough.

Lude Transmission is a worm gear screw jack supplier for 16 years,it has trapezoidal screw jack,ball screw jack,stainless screw jack and bevel gear screw jack. OEM and small order are acceptable. If you have any need for screw jacks,just feel free to contact us. Our website:https://www.ludetransmission.com/

评论

发表评论